Brill Power publishes poster at the Oxford Battery Modelling Symposium

28th March 2024, Oxford, UK – Just like any system, batteries too degrade with time (calendar-ageing) and usage (cycle-ageing). Slowly occurring side reactions within the battery eat away the active ions and electrode materials which cause a gradual decline in overall battery performance. This is what battery experts refer to as “battery degradation”.

Although battery degradation is a slow process, it has significant performance implications over the long term. For stationary battery storage assets, reduced efficiency and shortened lifespan mean a lower Return on Investment (ROI). For Electric Vehicles (EVs), this results in reduced vehicle range and longevity. The cost of an EV battery typically amounts to about 40% of the vehicle cost, which makes battery replacements very expensive. To counter this, battery oversizing is widely practised, but this further increases costs and reduces efficiency. Battery degradation can also pose significant safety risks if not managed properly over the system’s lifetime.

Battery degradation results in capacity and power fade, meaning batteries store less charge and become less efficient as they degrade.

The rate and extent of battery degradation depends on the following factors:

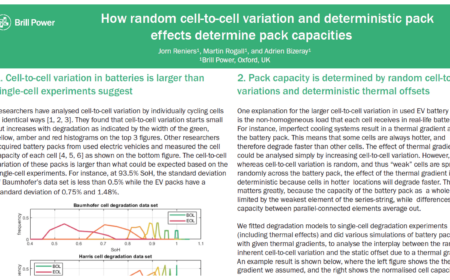

In addition, cells within the same battery pack degrade differently due to slight variations in above-mentioned factors. Learn more about cell-to-cell variations and how BrillCore solves them in this exclusive WHITEPAPER – Solving the battery cell-to-cell variations conundrum for energy storage systems – Brill Power.

Battery degradation is monitored by estimating what is aptly called ‘State of Health (SoH)’. There is no standardised definition of SoH but a capacity factor is predominantly used as a State of Health metric. This capacity factor measures capacity fade as a fraction of the battery’s initial capacity. This is an indication of how much energy a fully charged battery can store as it ages compared to when it was brand new. However, other metrics may be used to get a more comprehensive picture of the actual State of Health of a battery. For instance, a resistance factor measuring the increase in battery internal resistance is often used to account for power fade, which can be the primary limiting factor in high-power applications.

In EVs for example, a battery is typically said to have reached end-of-life (EOL) when its capacity factor reaches around 80%. Hence, EV batteries are generally expected to last for about 7 to 8 years, which is also a typical warranty term offered by the vehicle manufacturers.

Brill Power’s Battery Intelligence Platform comprises three technologies that bring transformational advances in battery longevity, performance, cost and sustainability:

Our platform can even be used to enhance performance and lifespan of batteries in second-life applications, where batteries no longer fit for one application (like EVs) and are converted for use in another application (like residential energy storage). Moreover, the platform being chemistry-agnostic can even accommodate more heterogeneous batteries consisting of modules of varying chemistries and degradation levels.

Work with Brill Power’s whole platform to fully benefit from an end-to-end solution and optimise management of your battery energy.

Battery degradation is a critical issue impacting various sectors, from stationary storage to electric vehicles, but it does not have to be the Achilles heel of batteries. Understanding its causes and implications is essential for addressing performance decline and safety risks over time. Brill Power’s innovative Battery Intelligence Platform goes beyond the capabilities of conventional battery management systems by leveraging advanced technologies like BrillCore, BrillOS, and BrillAnalytics to prolong battery lifespan, optimise performance, and ensure safety.

Blog by Hassan Ali Mandasorwala, Controls Engineer in Software, Adrien Bizeray, Chief Data Scientist and Christoph Birkl, CEO